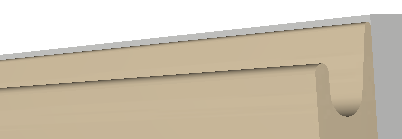

Profiles can be selected and viewed/edited on the DoorMaster LT > Profile Doors page of the Catalog/Drawing Properties.

Simply select the Series, Style and Version from the drop lists, in this case the Series 3 Style 6 as shown.

Ensure the Profile is On and if you want to use Machining then the purchase of the applicable licence is required.

Click on the image to open the selected Profile's Properties which allows you to view, change and save new settings.

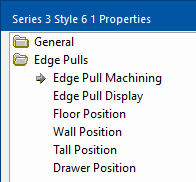

- The chosen door's settings include an Edge Pull category with six (6) associated pages.

Edge Pull Machining

The Edge Pulls > Edge Pull Machining page provides the options to input the required Pull Machining Settings.

When machined on a flatbed router where the parts are nested together, doors/fronts with Edge Pulls are spaced apart to allow for the tooling along the edge. This is because the Edge pull profiling tools are often quite wide and require a pocket for entry/exit as they cannot be plunged.

Explanation of Options

|

Options |

Explanation |

| Clearance | The gap between the Edge Pull tool and the side of pocket (to ensure there is a sufficient margin when the Edge Pull tool is plunged into the pocketed area). |

| Edge Overlay | The distance the centre of the Edge pull tool pushes into the side of the door. |

| Pocket Overlay | The distance the pocket overlaps the edge of the door. |

| Pocket Depth | The depth of the pocket. |

| Pocket Layer | The dxf layer name for the pocketing tool path. |

| Pocket Tool Radius | The radius of the pocketing tool. |

| Profile Depth | The depth the Edge Pull tool is plunged to (this is usually the same or very slightly less than the pocket depth). |

| Profile Layer | The dxf layer name for the Edge Pull toolpath. |

| Profile Tool Radius | The radius of the Edge Pull tool. |

- The size of the pocket is determined by the Edge pull tool radius and clearance.

- The exported machining also includes an additional spacing dxf layer to ensure other parts are not nested where the Edge Pull tool will route.

- See Nesting and Machining Notes below for further machining information.

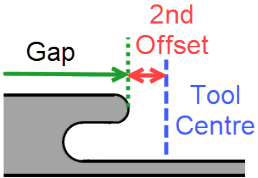

Length of Edge Profile Tooling

The toolpath for the Edge pull profile is calculated so that the specified gaps, set on the Edge Pulls > Cabinet Positions page, are measure to the edge of the physical door front accounting for the shape of the tool as shown below. This means the calculation uses the Second Offset found on the Edge Pull Display page.

If the gap is set to be zero however (so that the Edge profile runs the entire side of the door), then the 2nd Offset is ignored and the tool runs an extra 1mm beyond the edge of the door.

Pocket Size

The pocket size is calculated using the width of the profile tool and the clearance. However, if the Pocket tool is larger than the profile tool plus the clearance on both sides, then the Pocket Tool's width is used instead.

Edge Pull Display

The Edge Pulls > Edge Pull Display page allows the look of the 3D can be adjusted using these settings.

The 3D will adjust to a best fit using these setting, but will try and not corrupt if the settings are out of a usable range. For example, if the defined 3D shape is wider than the thickness of the material.

Position - Floor, Wall, Tall, Drawer

The Edge Pulls > Cabinet Position pages options control the positioning and side of the Edge Pull on the different doors types and drawer fronts.

The Edge Pulls can be enabled on the different edges of the door with the measurements defining any gap each side of the Edge Pull profiling.

There are drawbacks in specifying default settings for Edge Pull side and its gaps for all doors of a certain type:-

- The hinged side may vary from door to door.

- The dimensions of each door may vary.

The following settings compensate for this.

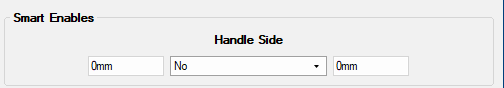

Smart Enables

The Smart Enables specify the settings to be used on the natural Handle Side of the door (i.e. the opposite side to the hinge).

The gap measurements here are taken as if being viewed from the centre of the door outwards towards the profiled edge.

For example, if the handle side was on the Left of the door then the Smart Enable gap to the right of the Yes/No will be towards the top of the door and the one on the left would be used on the bottom (and visa versa if handle was on the Right side of the door).

Also note that:-

- Smart enabled profiles will be in addition to any others specified.

- Smart Enables are not available on Drawer fronts - see Extras for Tall and Drawer

Centre and Use Length

Setting the Centre and Use Length option to Yes will ignore any gaps specified to each side of the Edge Pull profile.

The Edge Pull will be centred along the side of the door and be of the length specified (leaving even gaps to each side).

Extras - Tall and Drawer

Extras are only available for Tall doors and Drawer Fronts.

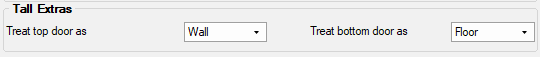

Tall Doors

For doors in Tall cabinets it may be that the Edge Pulls are placed along the 'Handle Side', but when there is a pair of doors (one above the other) the Edge Pull position may need to be different. For example, an upper door may need the Edge Pull along its bottom side and the lower along its top.

The Extras allow these doors to be treated as if they were of a different type.

Drawer Fronts

Similarly with Drawers Fronts, the top and bottom drawer fronts on a set of drawers may need to be treated differently from the ones in-between.